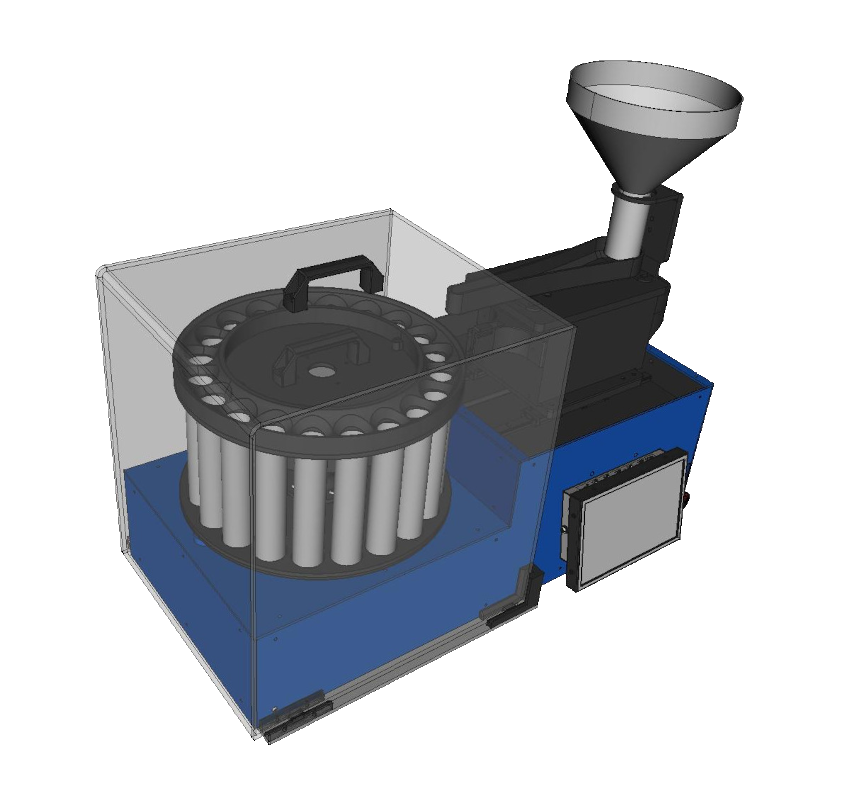

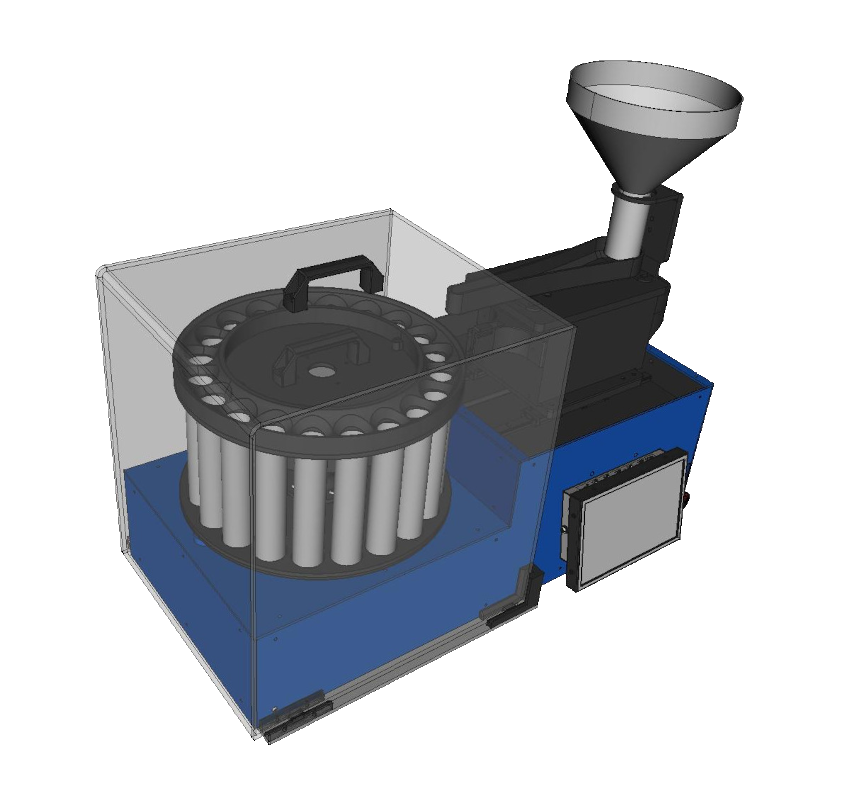

Percentage Cutoff Machine

Uses a rotary mechanism to split a maximum of 10,000c rough pre-sized stones into 12, 16 and 20-way dispenser units. Controlled using a touchscreen.

Providing technical consulting and sorting equipment R&D for the diamond industry.

We are continually developing a range of machines for working with rough goods.

Uses a rotary mechanism to split a maximum of 10,000c rough pre-sized stones into 12, 16 and 20-way dispenser units. Controlled using a touchscreen.

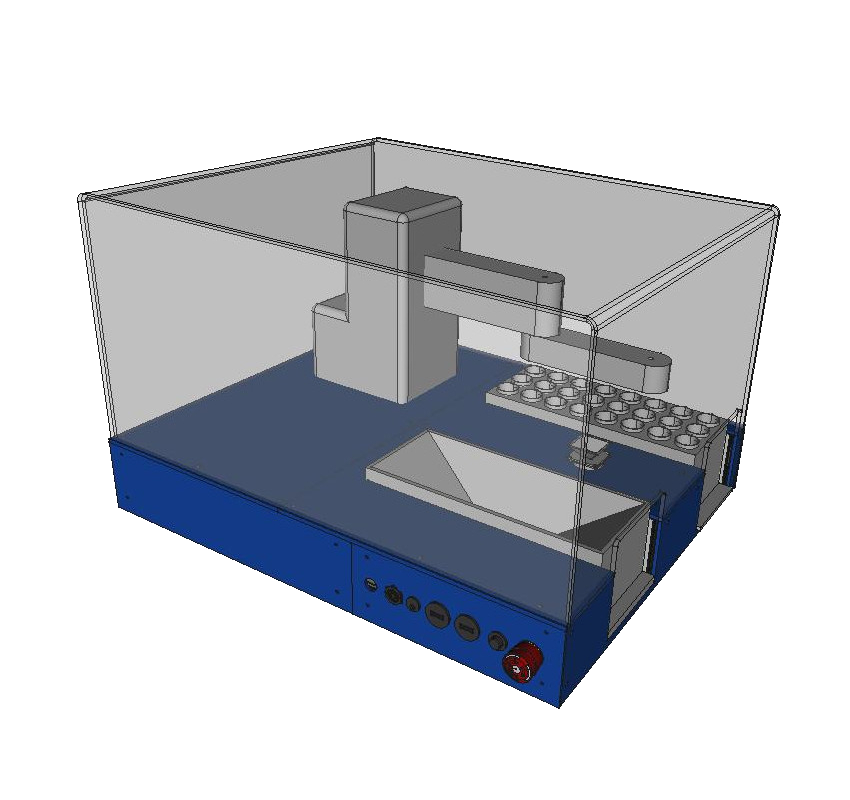

Automates the process of sorting and splitting batches of stones into pots of explicit weight bands, as specified by the operator. These weight bands can form dynamic, or predetermined sales lots. The machine is operated through a cross platform application.

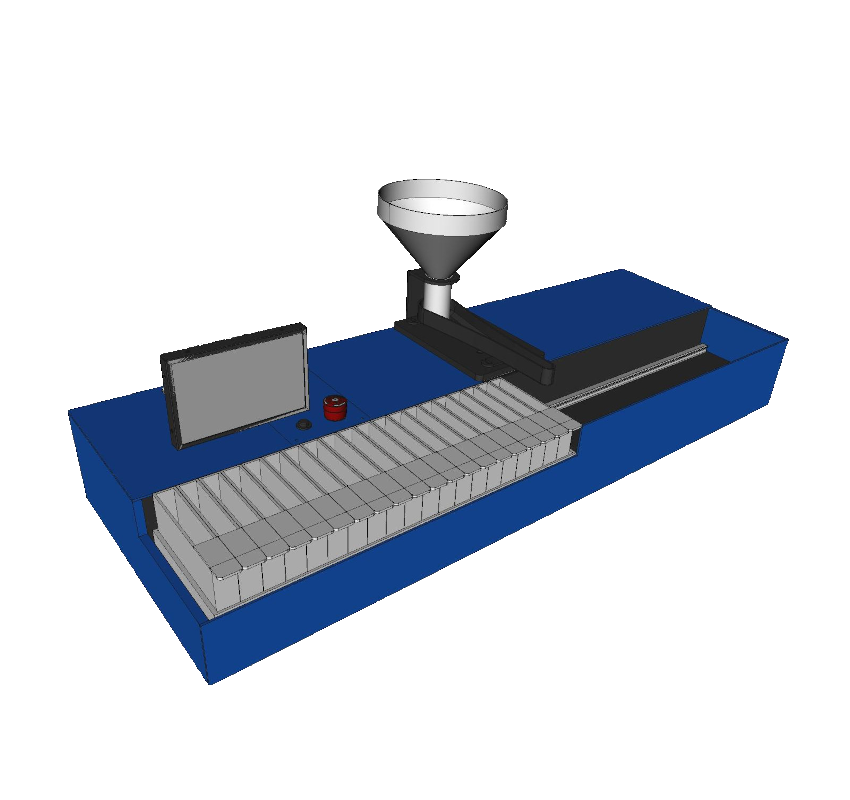

Linear version of the standard PCM, this machine simplifies the mechanics and enables a greater range of pots (2-20) to be used. Less compact than the standard PCM but more flexible.

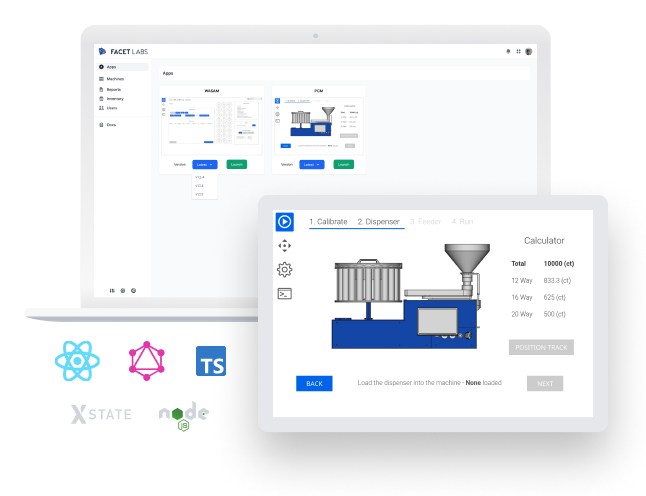

We use modern programming frameworks and techniques to provide cross platform control interfaces that can be run from almost any device.

Leveraging web technologies gives us a rich ecosystem of tooling, so we can concentrate on providing functionality, rather than reinventing the wheel.

All machine controls are exposed through APIs, allowing machine-to-machine as well as application-to-machine communication.

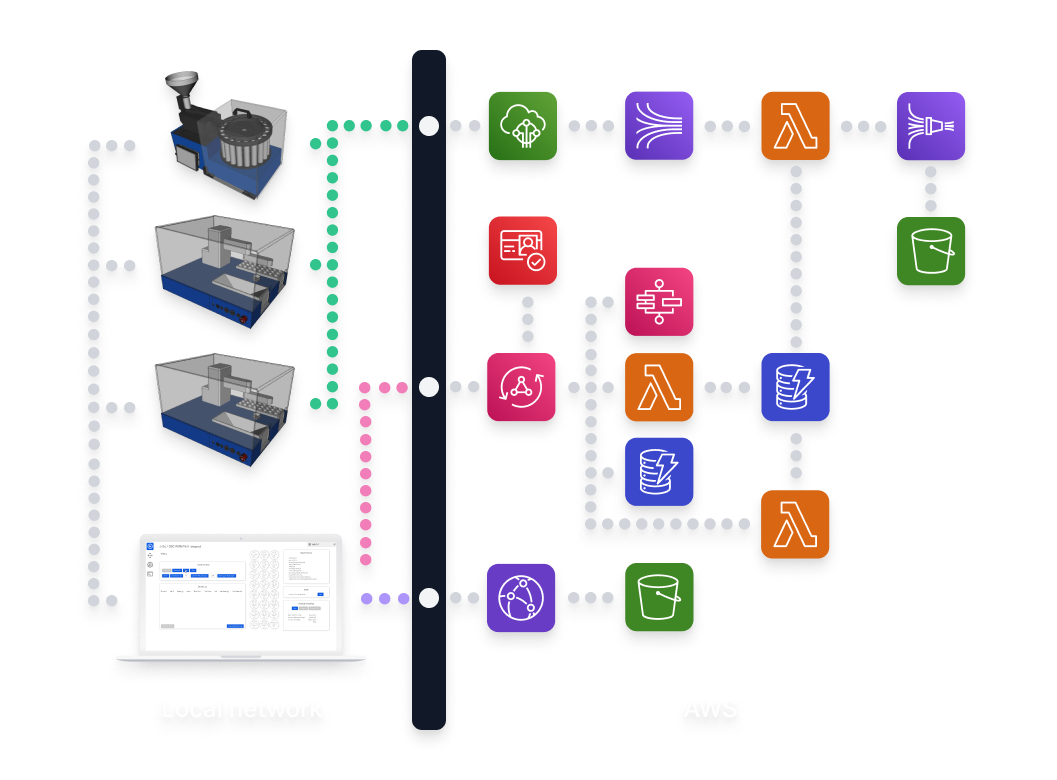

Local connections provide realtime application data while the cloud is used to deliver long term storage and cross machine data set analytics and processing.

Centralised logging and remote update procedures are built on top of secure, managed cloud services, enabling us to develop features quickly.

We hold AWS SA & DevOps professional certificates.

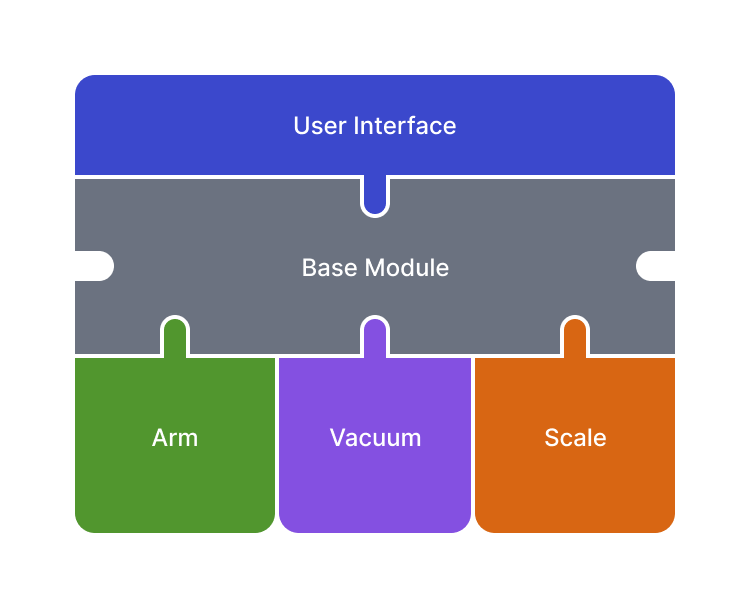

The use of modular subsystems help us deliver adaptable machine designs that are easy to maintain and upgrade capable.

The modules provide bounded domains for reliable testing and simulation of software and electrical components.

Smaller, self-contained systems with standardised interfaces make agile workflows far more effective.

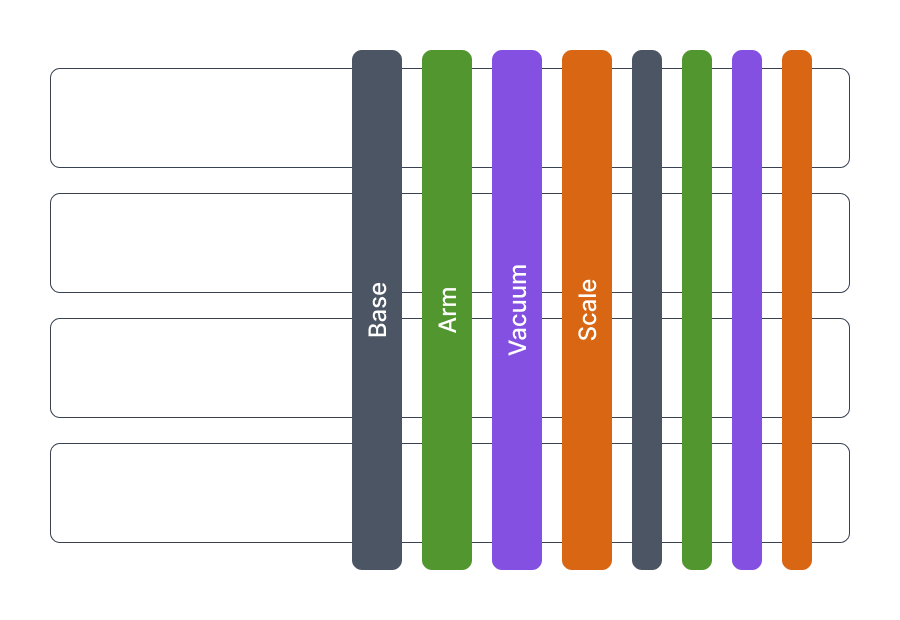

We like to work in an iterative and reactive way, getting an end-to-end product up and running as quickly as possible, before refining and optimising.

Working this way requires a short feedback cycle and so we try to manufacture as much as possible in-house while prototyping.

Vertically sliced and decoupled blocks of work help drive fast iterations, without breaking other systems.

We may be a small team, but we get a lot done!

40 years working in the diamond industry, spanning R&D and project management roles.